In order to ensure safety and guarantee product quality, we implement high standards for raw materials, production processes, and finished product testing.

Raw materials: Raw materials are strictly inspected before entering the workshop to ensure that they meet the process needs.

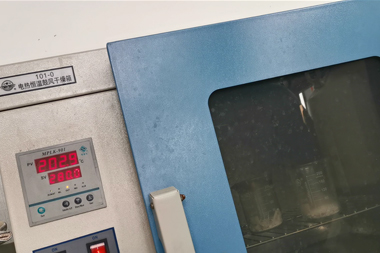

Production process: During the production process, we will strictly control each process to ensure that all parameters, such as formula, temperature, time, etc., meet the production specifications.

Product testing: All batches of products are sampled for multiple parallel tests to ensure effective chlorine content, pH value, moisture, particle size distribution, hardness, etc., meeting the needs of different application scenarios.

Packaging inspection: In addition to official testing, we also conduct our own testing on packaging quality, such as strength of packaging materials and sealing performance. After sub-packaging, we also conduct a unified inspection of the packaging to ensure the complete and well-sealed packaging, and the clear and accurate label.

Sample retention and record keeping: Samples and test records are kept from all product batches to ensure traceability in the event of quality problems.

Sample Room

Combustion Experiment