Sodium dichloroisocyanurate (abbreviation SDIC) is one kind of chlorine chemical disinfectant commonly used as a disinfectant for sterilization, it is widely used in industrial disinfecting applications, especially in the disinfection of sewage or water tanks. In addition to being used as a disinfectant an industrial deodorant, SDIC is also commonly used in wool anti shrink treatment and bleaching in the textile industry.

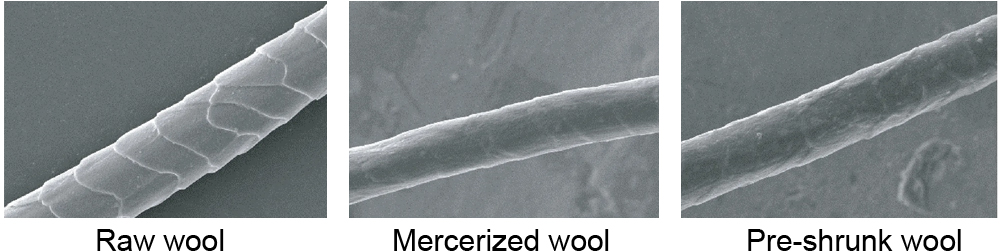

There are many scales on the surface of wool fibers, and during the washing or drying process, the fibers will lock together by these scales. As the scales can only move in one direction, the fabric has shrunk irreversibly. This is why wool fabrics must be shrink-proofed. There are many different types of shrink-proofing, but the principle is the same: to eliminate the scales of the wool fiber.

SDIC is a strong oxidizer in water and its aqueous solution can uniformly release hypochlorous acid, which interacts with protein molecules in the wool cuticle layer, breaking some bonds in the wool protein molecules. Because the protruding scales have higher surface activity energy, they preferentially react with SDIC and are removed. Wool fibers without scales can slide freely and no longer lock together, so the fabric no longer shrinks significantly. In addition, using SDIC solution to treat wool products can also prevent adhesion during wool washing, i.e. the occurrence of “pilling” phenomenon. The wool that has undergone anti shrink treatment shows almost no shrinkage and is machine washable and facilitate dyeing. And now treated wool has a high whiteness and good hand feel (soft, smooth, elastic) and a soft and bright luster. The effect is so-called mercerization.

Generally, using a 2% to 3% solution of SDIC and adding other additives to impregnate wool or wool blended fibers and fabrics can prevent pilling and felting of wool and its products.

The processing is usually carried out as follows:

(1) feeding the wool strips;

(2) Chlorination treatment by using SDIC and sulfuric acid;

(3) Dechlorination treatment: treated with sodium metabisulfite;

(4) Descaling treatment: using descaling solution for treatment, the main components of the descaling solution are soda ash and hydrolytic protease;

(5) Cleaning;

(6) Resin treatment: using resin treatment solution for treatment, wherein the resin treatment solution is a resin treatment solution formed by composite resin;

(7) Softening and drying.

This process is easy to control, will not cause excessive fiber damage, effectively shortens the processing time.

The usual operating conditions are:

The pH of bathing solution is 3.5 to 5.5;

The reaction time is 30 to90 min;

Other chlorine disinfectants, such as trichloroisocyanuric acid, sodium hypochlorite solution and chlorosulfuric acid, can also be used for wool shrinkage, but:

Trichloroisocyanuric acid has very low solubility, preparing the working solution and using is very troublesome.

Sodium hypochlorite solution is easy to use, but has a short shelf life. This means that if stored for a period of time, its effective chlorine content will drop significantly, resulting in increased costs. For sodium hypochlorite solution that has been stored for a period of time, the effective chlorine content must be measured before use, otherwise the working solution of a certain concentration cannot be prepared. This increases labor costs. There are no such problems when selling it for immediate use, but it greatly limits its application.

Chlorosulfonic acid is highly reactive, dangerous, toxic, emits fumes in the air, and is inconvenient to transport, store, and use.

Post time: Aug-08-2024