Melamine Cyanurate (MCA) is an important compound widely used in the flame retardant industry, especially suitable for flame retardant modification of thermoplastics, such as nylon (PA6, PA66) and polypropylene (PP). High-quality MCA products can significantly improve the flame retardant properties of materials while maintaining the material’s mechanical properties and processing properties. However, the quality of MCA products on the market varies, and how to choose a high-quality MCA has become an important issue faced by users.

First, understand the basic properties of melamine cyanurate

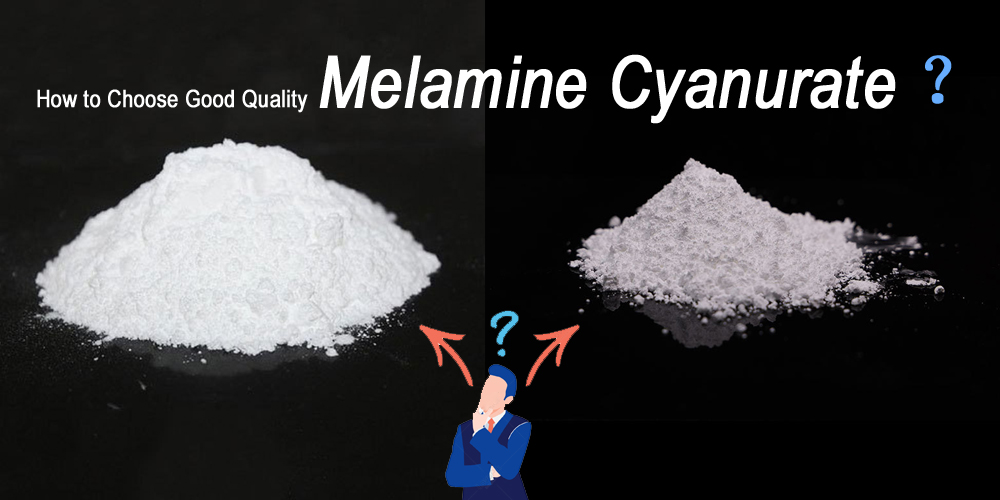

Melamine cyanurate is a white powder or granule with the following properties:

1. Excellent flame retardant performance: MCA releases inert gas and nitrogen through endothermic decomposition to form a heat insulation layer, which inhibits combustion.

2. Good thermal stability: MCA is stable at high temperatures and can adapt to a variety of processing conditions.

3. Non-toxic and environmentally friendly: As a halogen-free flame retardant, MCA complies with international environmental regulations (such as RoHS and REACH) and is widely used in electronic appliances and automobile fields.

Understand the production process of MCA

The production process of MCA There are currently two main production processes on the market:

Urea method

Melamine is added during the pyrolysis of urea to generate ICA, or urea and melamine are eutectic to generate crude MCA in one step. Acid boiled, washed, dried and refined to obtain the finished product. Production costs are low. The cost of raw materials is only about 70% of that of the cyanuric acid method.

cyanuric acid method

Add equal amounts of melamine and ICA to water to make a suspension, react for several hours at 90-95°C (or 100-120°C79), continue to react for a period of time after the slurry becomes obviously viscous, and filter. , dried and crushed to obtain the finished product. The mother liquor is recycled.

Pay attention to MCA’s core quality indicators

When choosing an MCA, you need to focus on the following quality indicators:

Purity

High purity MCA is the basis for quality products. Generally speaking, the purity of high-quality MCA should be no less than 99.5%. The higher the purity, the better its flame retardant properties, while avoiding the impact of impurities on material properties.

Whiteness

The higher the whiteness, the more refined the processing technology of MCA and the lower the impurity content. The high whiteness of MCA not only improves the appearance quality, but also avoids any impact on the color of the end product.

Particle size distribution

The size and distribution of particle size directly affect the dispersion and processing performance of MCA in the polymer matrix. High-quality MCA usually has a uniform particle size distribution, and the average particle size is controlled per clients’ need (usually equal to or less than 4 microns), which can not only ensure dispersion but also reduce the impact on the mechanical properties of the material.

Moisture

MCA with low moisture content can reduce the risk of hydrolysis of polymer materials during high-temperature processing and ensure excellet compatiblity. The moisture content of high-quality MCA is usually less than 0.2%.

Evaluate supplier qualifications and service capabilities

To choose high-quality MCA products, in addition to paying attention to the product itself, you also need to examine the supplier’s qualifications and service capabilities:

Certification qualifications

High-quality suppliers usually have passed ISO9001 quality management system certification, ISO14001 environmental management system certification, etc. In addition, products must comply with international environmental regulations such as REACH.

Production capacity and technical support

Suppliers with modern production facilities and R&D teams can ensure a stable supply of products and provide customers with technical support and solutions.

Customer reputation

Learn about a supplier’s reputation and service levels through customer reviews. If the supplier’s products are widely used by well-known companies, their reliability and quality are more guaranteed.

Logistics and after-sales service

High-quality suppliers usually have a complete logistics system and can respond quickly to customer needs. At the same time, they should also provide good after-sales service, including technical support, problem feedback, etc.

On-site visits and sample testing

Before identifying cooperative suppliers, on-site inspections are an important means to verify production capabilities. By visiting the factory, you can understand its production equipment, process flow and quality management level. In addition, sample testing is also an important step to ensure that the product meets the requirements.

Sample testing recommendations include the following:

– Purity analysis: Through laboratory testing, confirm whether the actual purity of the product meets the requirements.

– Particle size test: Particle size distribution is measured using a particle size analyzer.

Through test data, you can understand product performance more intuitively and make scientific purchasing decisions.

By following the above steps, you will be able to find a high-quality MCA supplier that can provide a stable flame retardant solution for your project.

Post time: Dec-02-2024