As a multifunctional chemical raw material, sulfamic acid plays an important role in the dye industry. Its unique chemical properties make it widely used in dye synthesis and dyeing processes. It can not only be used as a catalyst auxiliary to improve the efficiency of dye synthesis, but also can be used to adjust the pH value of the dyeing process to optimize the dye uptake and color fastness. This article explores the critical roles sulfamic acid plays in dye manufacturing and its benefits for the industry.

1.Eliminating excess nitrite

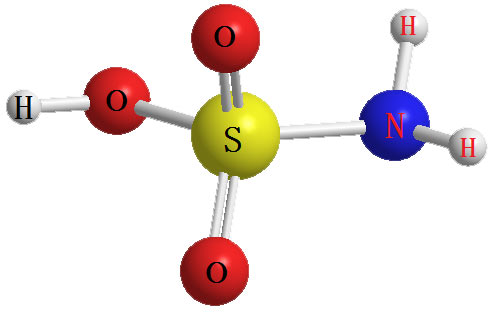

In dye synthesis, diazotization reaction is a key step in the production of azo dyes. The reaction usually uses sodium nitrite and hydrochloric acid to produce nitrous acid, which reacts with aromatic amines to form diazonium salts. However, if excess nitrite is not treated in time, it will cause environmental pollution, and excess nitrite may react with dye molecules, affecting the color and light stability of the dye. Therefore, aminosulfonic acid is widely used in the dye industry as an efficient and safe nitrite eliminater. The reaction principle is as follows:

NaNO₂ + H₃NSO₃ → N₂ + NaHSO₄ + H₂O

Aminosulfonic acid reacts quickly with nitrite and can effectively convert excess nitrite into harmless nitrogen gas.

- Specific applications

Post-treatment of diazotization reaction: After the diazotization reaction is completed, add an appropriate amount of aminosulfonic acid solution and stir the reaction for a period of time to completely eliminate the excess nitrite.

Dye intermediate purification: In the preparation process of dye intermediates, aminosulfonic acid can be used to remove residual nitrite and improve the purity of the product.

Wastewater treatment: For dye wastewater containing nitrite, aminosulfonic acid can be used for treatment to reduce the nitrite concentration in the wastewater and reduce pollution to the environment.

2. Stabilization of Dye Solutions

In the dye industry, the stability of dye solutions is crucial for ensuring uniform and consistent coloring. Sulfamic acid acts as a stabilizing agent, preventing premature hydrolysis and degradation of dye molecules during storage and application. This characteristic is particularly valuable in reactive dyes, where maintaining chemical integrity is essential for achieving vibrant and long-lasting colors.

3. pH Control

The effectiveness of many dyes depends on maintaining a specific pH level. Sulfamic acid, known for its mild acidity, serves as a pH adjuster in dye baths. By precisely controlling the pH, it ensures optimal conditions for dye fixation onto fibers, enhancing the overall dyeing efficiency and reducing the risk of uneven coloring or defects.

4. Descaling and Cleaning Dye Equipment

Dye production and application often lead to the accumulation of scale and residues in equipment. Sulfamic acid’s powerful descaling properties make it an excellent cleaning agent for removing these deposits without damaging the machinery. Regular cleaning with sulfamic acid not only improves equipment lifespan but also ensures that the dyeing process remains uncontaminated, resulting in higher-quality products.

5. Improving Dyeing Quality on Fibers

Sulfamic acid enhances the penetration and fixation of dyes on fibers such as cotton, wool, and synthetic materials. By creating a suitable acidic environment, it ensures better absorption and bonding of dye molecules to the fiber, leading to more vibrant and durable colors. This is particularly useful in textile industries that require high-quality finishes.

Sulfamic acid’s role in the dye industry is multifaceted, spanning from stabilizing dye solutions to improving dye quality, cleaning equipment, and treating wastewater. Its unique properties and environmentally friendly characteristics make it a valuable asset for manufacturers seeking efficiency and sustainability.

Post time: Dec-31-2024