Sodium Dichloroisocyanurate (NaDCC for short) is an efficient, safe and widely used chemical disinfectant. With its excellent chlorination properties, NaDCC has become a very promising treatment agent for wool shrinkage prevention.

The necessity of wool shrinkage prevention

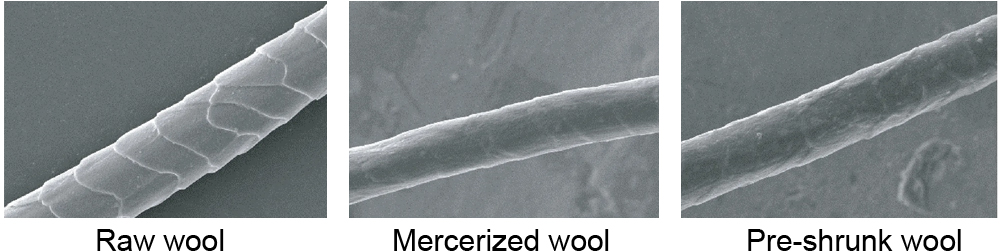

Wool is a natural protein fiber with the characteristics of softness, warmth retention and good hygroscopicity. However, wool is prone to shrinking when washed or wet rubbed, which changes its size and appearance. This is because the surface of wool fibers is covered with a layer of keratin scales. When exposed to water, the scales will slide and hook each other, causing the fibers to entangle and shrink. As a result, shrinkage prevention becomes an indispensable part of the wool textile processing process.

Basic properties of sodium dichloroisocyanurate

NaDCC, as an organic chlorine compound, contains two chlorine atoms and an isocyanuric acid ring in its molecular structure. NaDCC can release hypochlorous acid (HOCl) in water, which has strong oxidizing properties and excellent disinfection properties. In textile processing, the chlorination of NaDCC can effectively modify the surface structure of wool fibers. Thereby reducing or eliminating the tendency of wool fibers to feel shrinkage.

Application principle of NaDCC in wool shrinkage prevention

The principle of NaDCC in wool shrinkage prevention is mainly based on its chlorination characteristics. The hypochlorous acid released by NaDCC can react with the keratin scales on the surface of wool to change its chemical structure. Specifically, hypochlorous acid undergoes an oxidation reaction with the protein on the surface of wool fibers, making the scale layer smoother. At the same time, the friction between the scales is weakened, reducing the possibility of wool fibers hooking each other. It can achieve shrinkage prevention while maintaining the original properties of wool fibers. In addition, NaDCC has good solubility in water, the reaction process is relatively stable, and its decomposition products are environmentally friendly.

Advantages of sodium dichloroisocyanurate

Long shelf life

① The chemical properties of sodium dichloroisocyanurate are stable and it is not easy to decompose at room temperature. It will not deteriorate even if stored for a long time. The content of active ingredients remains stable, ensuring the disinfection effect.

② It is resistant to high temperatures and will not decompose and inactivate during high-temperature disinfection and sterilization, and can effectively kill various microorganisms.

③ Sodium dichloroisocyanurate has strong resistance to external environmental factors such as light and heat, and is not easily affected by them and becomes ineffective.

These excellent properties make sodium dichloroisocyanurate a disinfectant that is very suitable for long-term storage and use, and is widely used in many fields such as medical, food, and industry.

Easy to operate

The use of NaDCC is relatively simple and does not require complex equipment or special process conditions. It has good water solubility and can be directly in contact with wool fabrics for continuous or intermittent treatment processes. NaDCC has a low reaction temperature requirement and can achieve efficient shrinkage-proofing at room temperature or medium temperature. These characteristics greatly simplify the operation process.

Wool performance remains good

NaDCC has a mild oxidation effect, which avoids excessive oxidative damage to wool fibers. The treated wool maintains its original softness, elasticity and gloss, while effectively preventing the problem of felting. This makes NaDCC an ideal wool shrinkage-proofing agent.

Process flow of NaDCC wool shrinkage-proofing treatment

In order to achieve the best wool shrinkage-proofing effect, the treatment process of NaDCC needs to be optimized according to different wool textile types and production requirements. Generally speaking, the process flow of NaDCC in wool shrink-proof treatment is as follows:

Pretreatment

Wool needs to be cleaned before treatment to remove dirt, grease and other impurities. This step usually includes cleaning with a mild detergent.

Preparation of NaDCC solution

According to the thickness of the wool fiber and processing requirements, a certain concentration of NaDCC aqueous solution is prepared. Generally, the concentration of NaDCC is controlled between 0.5% and 2%, and the specific concentration can be adjusted according to the difficulty of wool treatment and the target effect.

Chlorine treatment

Wool is soaked in a solution containing NaDCC. Chlorine selectively attacks the scale layer on the surface of the wool fiber, reducing its shrinkage. This process requires precise control of temperature and time to avoid damaging the wool fiber. The general treatment temperature is controlled at 20 to 30 degrees Celsius, and the treatment time is 30 to 90 minutes, depending on the fiber thickness and treatment requirements.

Neutralization

In order to remove residual chlorides and prevent further damage to the wool, the wool will undergo a neutralization treatment, usually using antioxidants or other chemicals to neutralize the chlorine.

Rinsing

The treated wool needs to be thoroughly rinsed with water to remove any residual chemicals.

Finishing

To restore the feel of the wool, increase the gloss and softness, softening treatment or other finishing operations may be performed.

Drying

Finally, the wool is dried to ensure that there is no residual moisture to avoid the growth of bacteria or mold.

Sodium dichloroisocyanurate (NaDCC), as an efficient and environmentally friendly wool shrink-proof treatment agent, is gradually replacing the traditional chlorination treatment method with its excellent chlorination performance and environmental friendliness. Through the reasonable use of NaDCC, wool textiles can not only effectively prevent felting, but also maintain softness, elasticity and natural luster, making them more competitive in the market.

Post time: Sep-13-2024