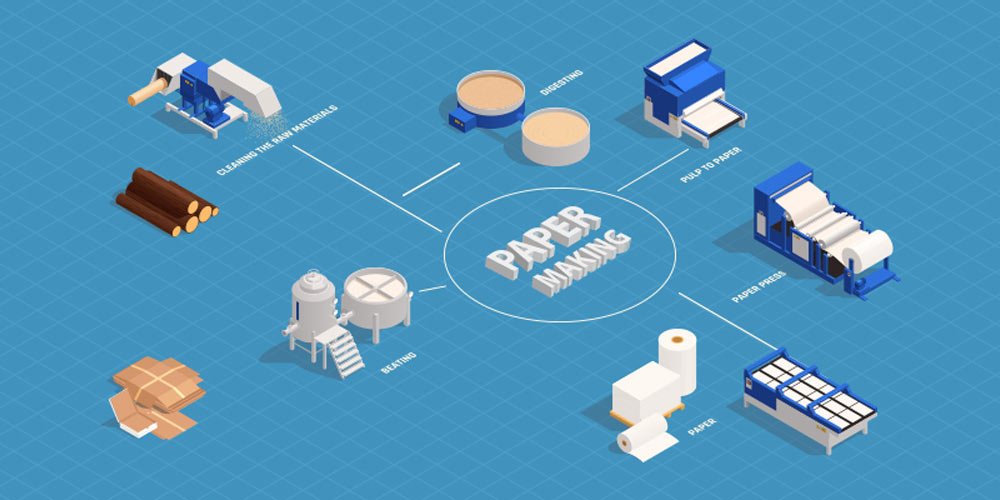

In the papermaking industry, Aminosulfonic Acid is widely used in pulp bleaching, paper sizing and other links due to its unique chemical properties, which is of great significance to improving paper quality and reducing production costs. This article will deeply explore the specific application, mechanism of action and impact of aminosulfonic acid on the development of the papermaking industry.

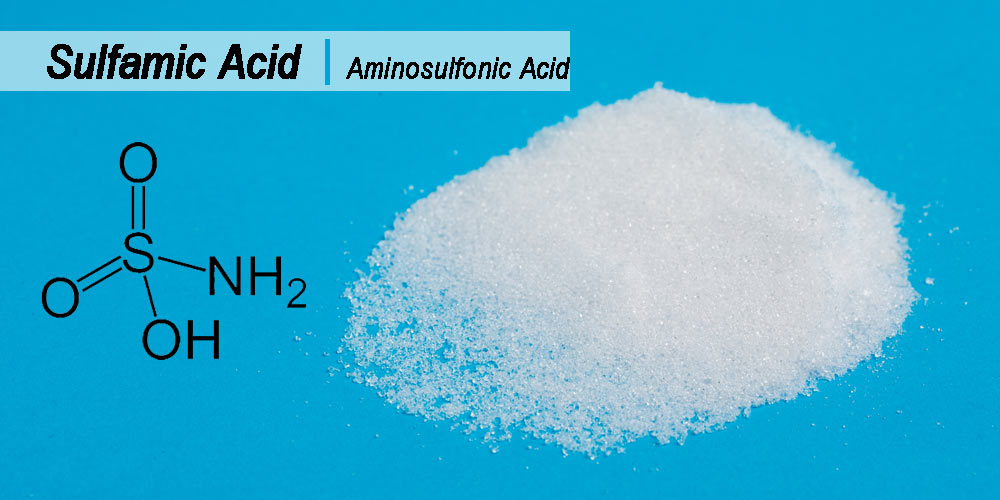

Aminosulfonic acid (aminosulfuric acid) is a white crystal that is easily soluble in water and has strong acidity. Its molecular structure contains amino and sulfonic acid groups, which gives it unique reactivity. In the papermaking process, aminosulfonic acid mainly plays the following roles:

Complexation: Aminosulfonic acid can form stable complexes with metal ions (such as iron, copper, etc.), thereby inhibiting the catalytic oxidation of metal ions on pulp and protecting cellulose.

Reduction: Under certain conditions, aminosulfonic acid can be used as a reducing agent to participate in the bleaching process of pulp and remove impurities such as lignin.

pH adjustment: Aminosulfonic acid has a strong buffering capacity and can adjust the pH value of pulp to provide a suitable environment for enzyme activity.

Application of aminosulfonic acid in papermaking

Pulp bleaching

Pulp bleaching is a key link in the papermaking process, the purpose of which is to remove impurities and pigments in the pulp and improve the brightness and purity of the paper.

The main function of aminosulfonic acid is to promote the decomposition of organic matter in the pulp and remove unnecessary pigments and impurities by providing an acidic environment. During the bleaching process, aminosulfonic acid can improve the brightness of the pulp under mild conditions while avoiding the negative effects of over-bleaching, such as fiber damage or excessive degradation of the pulp.

Paper sizing:

Improve the printing suitability of paper: The surface of the paper after sizing is smooth and flat, the ink is not easy to penetrate, and the printing effect is better.

Catalyst

Aminosulfonic acid can be used as a catalyst for certain chemical reactions, such as the curing of urea resin.

pH adjustment

In the papermaking process, bleaching, pulp treatment, wastewater treatment and other links require precise control of pH value. Too high or too low pH value will affect production efficiency and product quality. Therefore, it is a common operation to use aminosulfonic acid to adjust the pH value of the solution.

Aminosulfonic acid can quickly reduce the pH value of the solution and stabilize it within a suitable range. In this way, it can not only improve the bleaching effect, but also improve the efficiency of the wastewater treatment process, and avoid incomplete chemical reactions or other adverse effects caused by inappropriate pH.

Metal ion removal

In the production and treatment of pulp, metal ion contamination often affects the quality of the final product. For example, metal ions such as iron ions and copper ions have a negative impact on the color, strength and feel of paper. Aminosulfonic acid has good complexing ability and can react with these metal ions to form soluble metal salts, thereby removing metal impurities from pulp.

By adding aminosulfonic acid, not only can metal ions be effectively removed, metal ions can be prevented from catalyzing oxidation reactions, and the impact of these ions on paper quality can be avoided, thereby reducing the yellowing of pulp and ensuring the stability of the quality of the final product.

Preventing scaling

In the papermaking process, especially when using steam boilers and water treatment systems, the deposition of scale is a common problem. The accumulation of scale not only reduces thermal efficiency, but also may cause damage to equipment. Aminosulfonic acid has a unique role in this regard, and it can effectively prevent the formation of scale.

Factors affecting the amount of aminosulfonic acid

The amount of aminosulfonic acid will be affected by many factors, including:

Pulp type: Different types of pulp have different lignin content, fiber characteristics, etc., and the demand for aminosulfonic acid is also different.

Bleaching process: Different bleaching processes have different requirements for the amount of aminosulfonic acid.

Bleaching purpose: If the pulp is required to have higher whiteness or strength, the amount of aminosulfonic acid needs to be increased.

Other additives: The compatibility with other additives will also affect the amount of aminosulfonic acid.

Control of the amount of aminosulfonic acid

In order to achieve the best bleaching effect, the amount of aminosulfonic acid needs to be precisely controlled. Usually, the laboratory test and pilot test methods are used to determine the optimal amount of aminosulfonic acid by measuring the whiteness, strength and other indicators of the pulp.

As an important papermaking additive, aminosulfonic acid plays an increasingly important role in the papermaking industry. Its unique chemical properties and versatility make it have broad application prospects in pulp bleaching, paper sizing, etc. With the continuous advancement of papermaking technology, aminosulfonic acid will play a more active role in promoting the sustainable development of the papermaking industry.

Post time: Jan-02-2025